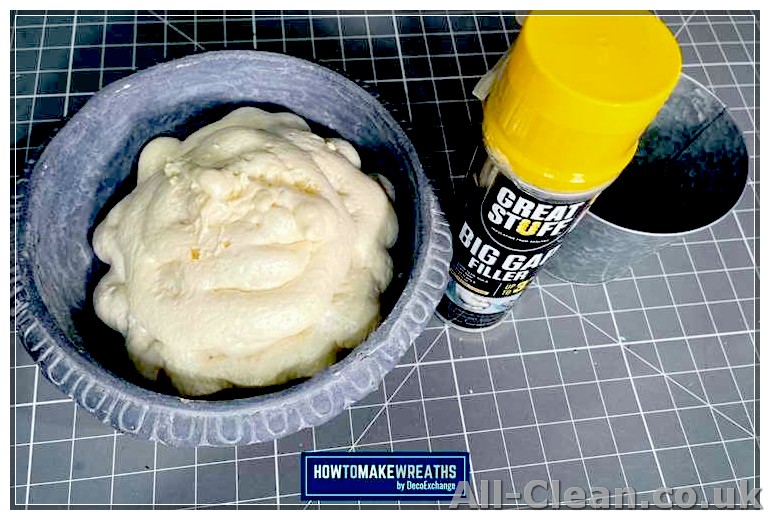

Expanding foam insulation is a versatile product that can be used for a variety of projects around the house. Whether you need to seal cracks, insulate windows, or reduce noise, expanding foam can be a valuable tool in your toolkit. However, there are a few dos and don’ts to keep in mind when using this product to ensure the best results.

First and foremost, it’s important to wear proper personal protective equipment (PPE) when working with expanding foam. This includes gloves, safety goggles, and a mask to protect yourself from the fumes. Additionally, make sure the area you’re working in is well-ventilated to prevent any breathing issues.

Before applying the foam, it’s crucial to thoroughly clean the area where it will be sprayed. Any dirt or debris can interfere with the foam’s adhesion and affect its performance. Once the area is clean, check for any electrical outlets or recessed lights that may need to be covered or protected before applying the foam.

When using expanding foam, it’s important not to overdo it. The foam expands and hardens once it’s sprayed, so start with a little and add more as needed. Applying too much foam can lead to wasted product and cleanup issues once it has hardened. Additionally, make sure to trim off any excess foam once it has cured to ensure a neat and tidy appearance.

Expanding foam can be a great way to increase insulation and decrease drafts in your home. However, it’s essential to consider the specific needs of each project before choosing the right type of expanding foam. Some foams are better for outdoor use, while others are designed for indoor applications. Be sure to read the product labels and instructions carefully to determine the best type of foam for your project.

Lastly, once the foam has hardened, it can be difficult to remove if it ends up in the wrong place. Therefore, it’s important to take your time and be careful when applying the foam. If you do get foam in an unwanted area, try wiping it off with a cloth or sponge soaked in warm, soapy water. For tougher stains, you may need to use a scraping tool or a solvent made specifically for removing expanding foam.

In conclusion, expanding foam insulation can be a useful tool for a variety of projects around the house. By following these dos and don’ts, you can ensure that your expanding foam projects are successful and help create a more comfortable and energy-efficient home.

The Dos of Using Expanding Foam Insulation

- Do assess the space: Before using expanding foam insulation, it’s important to evaluate the space you want to insulate. Determine whether the area is suitable for foam insulation and make sure it will effectively seal any gaps.

- Do use the right tool: When applying expanding foam insulation, it’s crucial to use the correct tool. A foam gun provides more control and precision compared to straw applicators, ensuring better application results.

- Do protect surrounding areas: Before using expanding foam insulation, cover nearby surfaces and objects with cardboard or other protective materials. This prevents the foam from accidentally sticking to or damaging any unintended surfaces.

- Do remove excess foam: Any foam that expands beyond the desired area should be promptly removed. Use a sharp knife or other appropriate tools to carefully trim away excess foam. This will create a neater and cleaner finish.

- Do check for live wires and pipes: Prior to applying expanding foam insulation, ensure that there are no live wires or pipes in the area. Cover or protect any exposed electrical outlets or recessed pipes to prevent the foam from causing any damage.

- Do start with a small application: When using expanding foam insulation for the first time, it’s recommended to start with a small application. This allows you to familiarize yourself with the foam’s expansion and curing process.

- Do work in a well-ventilated area: Expanding foam insulation releases fumes during application. It’s important to work in a well-ventilated space to avoid inhaling potentially harmful gases. Open windows and doors to increase air circulation.

- Do stop and seek help if necessary: If you encounter any difficulties or issues while applying expanding foam insulation, don’t hesitate to seek assistance. It’s better to ask for help and ensure proper insulation than to risk potential problems.

- Do check the expiration date: Before using expanding foam insulation, always check the expiration date on the product. Expired foam may not expand or cure properly, resulting in an ineffective insulation seal.

- Do use protective gear: To ensure personal safety, make sure to wear appropriate protective gear, such as gloves and safety goggles, when using expanding foam insulation. This can prevent skin irritation and eye injuries.

- Do clean up uncured foam immediately: If uncured foam comes into contact with unintended surfaces, clean it up promptly. Use a solvent, such as acetone or nail polish remover, to remove uncured foam before it fully hardens.

The Don’ts of Using Expanding Foam Insulation

- Don’t neglect protective measures: When working with expanding foam insulation, it’s essential to protect your skin, eyes, and respiratory system. Wear gloves, safety goggles, and a mask to avoid any irritation or harm.

- Don’t forget to clean up: After spraying expanding foam insulation, it can make a mess and leave residue. It’s crucial to clean up any spills or puffs immediately to prevent it from hardening and becoming difficult to remove.

- Don’t apply too much: Expanding foam insulation expands significantly, so be cautious not to overfill gaps or voids when applying. Using too much foam can cause structural damage and affect the effectiveness of the insulation. Apply prudently and in small amounts to ensure maximum expansion and efficiency.

- Don’t apply in a poorly ventilated area: Expanding foam insulation releases chemicals and fumes during the curing process. It’s important to work in a well-ventilated space to prevent the inhalation of harmful substances. Open windows and use fans to improve air circulation.

- Don’t use expired foam: Check the expiration date of the foam canister before use. Expired foam may not expand properly and could result in an ineffective seal. Using fresh foam ensures the best results and helps avoid any potential problems.

- Don’t forget to check for drafts: Before applying expanding foam insulation, inspect the area thoroughly to identify any drafts or openings that need sealing. By identifying and sealing these areas, you can improve energy efficiency and prevent air leakage.

- Don’t cut hardened foam with a spark-producing tool: If you need to trim or remove hardened foam, avoid using tools that generate sparks. Foam insulation is flammable, and using spark-producing tools can pose a significant fire risk. Instead, use a cutting tool that does not produce sparks.

- Don’t apply foam near heat sources: Avoid applying expanding foam insulation near heat sources such as pipes, lights, or fixtures that generate heat. The heat can cause the foam to expand too quickly, resulting in an uneven application and reducing its effectiveness.

- Don’t use expanding foam on cardboard or areas prone to pests: Expanding foam can degrade cardboard and may attract bugs. It’s best to avoid using foam insulation on cardboard surfaces and areas where pests are likely to be a problem. Choose alternative insulation options for such situations.

- Don’t use expanding foam if you suffer from asthma or respiratory conditions: The fumes and particles released from expanding foam insulation can exacerbate respiratory conditions such as asthma. If you have asthma or any other respiratory conditions, it’s best to avoid using expanding foam and opt for alternative insulation methods.

How can I remove ‘cured’ expanding foam?

If you’ve ever used expanding foam insulation, you know how messy it can be. While it’s a great product for sealing cracks and gaps around your home, it can be a pain to remove once it has cured. Here are some tips for removing cured expanding foam:

- Check the label: Before attempting to remove the foam, check the label on the can to see if there are any specific instructions for removal.

- Use a solvent: There are specific solvents available that can help soften and remove the cured foam. Make sure to read the instructions and use the solvent in a well-ventilated area.

- Scrape it off: If the foam has not fully cured and is still somewhat soft, you may be able to scrape it off with a sharp tool like a putty knife or a wire brush.

- Heat it up: Applying heat to the cured foam can sometimes soften it enough to make it easier to remove. Be careful not to use an open flame near the foam, as it can be flammable.

- Wash it away: If the foam is on a surface that can handle water, you can try washing it away with a powerful stream of water. This may not work for all surfaces, so be sure to test it in a small, inconspicuous area first.

- Use a hacksaw blade: In some cases, a hacksaw blade can be used to cut away sections of the cured foam. This method requires careful precision and should be used prudently.

Remember to always wear appropriate personal protective equipment (PPE) when working with expanding foam, including gloves, safety glasses, and a mask if you have asthma or other respiratory concerns.

Removing cured expanding foam can be a challenging task, but with the right techniques and tools, you can get the job done.